Introduction

Protective Eyewear for Workers – In various industries, such as construction, manufacturing, healthcare, and laboratories, protecting the eyes is paramount. The eyes are one of the most vulnerable parts of the human body, making proper eye protection an essential safety measure. According to the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH), thousands of workplace eye injuries occur each year, many of which could be prevented with the use of suitable protective eyewear.

Understanding the Dangers

Before delving into the solutions, it’s important to understand the types of hazards that can lead to eye injuries:

- Chemical Splashes: Chemicals used in manufacturing, cleaning, or laboratory settings can cause severe damage to the eyes. Even small amounts of corrosive substances can result in permanent injury.

- Physical Hazards: This includes flying debris, dust, and particles commonly found in construction sites or production floors. These can lead to scratches or punctures, which can be painful and debilitating.

- Optical Radiation: Certain work environments expose employees to harmful UV, laser, or infrared radiation, commonly encountered in welding, medical surgery, or various manufacturing processes.

- Biological Hazards: Healthcare professionals and researchers often face biological threats, such as bloodborne pathogens or contaminated substances, which can enter the body through the eyes.

Protective Eyewear Solutions

Protective Eyewear for Workers(ワークマンための保護メガネ) – To mitigate the risks associated with these hazards, various types of protective eyewear are available. Here’s a comprehensive look at different solutions to ensure maximum eye safety.

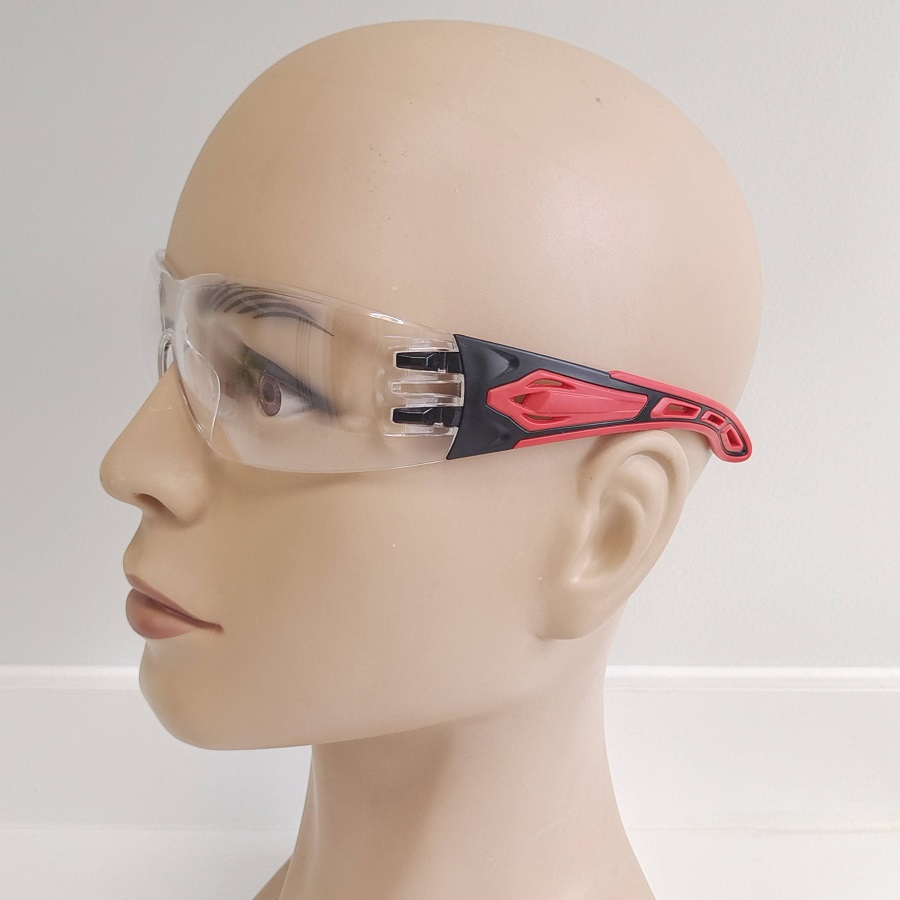

1. Safety Glasses

Safety glasses are designed to provide basic protection against flying objects, chemical splashes, and dust. They typically feature impact-resistant lenses and frames. Key characteristics include:

- Polycarbonate Lenses: These lenses are 10 times more impact-resistant than regular glass or plastic, making them an ideal choice for hazardous work environments.

- Side Shields: For added protection from debris coming from the sides, safety glasses may include side shields.

- Anti-Fog and Scratch-Resistant Coatings: These features enhance visibility and durability, ensuring the glasses maintain their integrity over time.

2. Goggles

For more extensive protection, goggles are a superior option. They provide a snug fit and cover the entire eye area, protecting against chemical splashes and fine particles. Essential aspects include:

- Ventilation: Some goggles include ventilation systems that allow for airflow while preventing contaminants from entering.

- Prescription Options: For those who need vision correction, prescription goggles can be custom made, combining vision clarity with safety.

- Chemical Resistance: Specific goggles are designed to protect against hazardous chemicals, making them suitable for laboratory and industrial environments.

3. Face Shields

Face shields offer a broader level of protection, covering not just the eyes but also the entire face. They are particularly beneficial in environments where there is a risk of chemical splashes, heat, or flying debris. Key features are:

- Full-Face Protection: Protects the facial area, minimizing exposure to harmful substances.

- Compatibility with Other PPE: Face shields can be used in conjunction with safety glasses or goggles for enhanced protection.

- Clear Visibility: Made from transparent materials, face shields allow for clear visual acuity while ensuring face coverage.

4. Welding Helmets

Welding tasks expose workers to intense light and heat, making specialized helmets necessary. These helmets come equipped with:

- Auto-Darkening Lenses: These lenses darken automatically when exposed to bright welding light, allowing for clear vision before and after the welding process.

- Adjustable Fit: Many helmets are adjustable to accommodate individuals’ comfort and preferences.

- Respiratory Protection: Some models are integrated with respiratory protection to safeguard against harmful fumes generated during welding activities.

5. Specialty Eyewear

Certain industries have specialized requirements, resulting in the development of unique eyewear options:

- Laser Safety Glasses: Protect against harmful laser radiation, often tailored to specific wavelengths.

- Dust Goggles: Specifically designed for high-dust environments, these goggles provide a secure fit and additional filtration features.

- Blue Light Blocking Glasses: In professions that involve prolonged computer use, these glasses can help reduce eye strain and prevent blue light exposure.

Choosing the Right Eyewear

Choosing the Right Eyewear

Selecting the right protective eyewear involves considering several factors:

- Type of Hazard: Identify the specific risks present in the work environment. For example, will the worker be exposed to chemicals, debris, or radiation?

- Fit and Comfort: Protective eyewear needs to fit well to ensure maximum protection. Ill-fitting gear can diminish safety and create discomfort.

- Compatibility with Other PPE: For jobs requiring multiple types of personal protective equipment, compatibility is crucial. Eyewear should comfortably integrate with helmets, masks, or ear protection.

- Lens Type: Depending on the work environment, it may be essential to choose scratch-resistant, anti-fog, or tinted lenses.

Training and Awareness

No matter how effective protective eyewear is, ongoing training and awareness are paramount. Employers should ensure that all employees:

- Understand the importance of using protective eyewear.

- Are trained on how to properly use and maintain their eyewear.

- Are familiar with the specific hazards they may encounter and the appropriate type of eyewear to address those risks.

Best Practices for Using Protective Eyewear

To maximize safety, employers and employees should adhere to several best practices when it comes to protective eyewear:

- Conduct a Risk Assessment: Employers must perform thorough assessments of the workplace to identify potential eye hazards. This evaluation should inform the selection of appropriate eyewear for employees.

- Provide Training: It’s vital to offer training sessions that educate employees on the importance of wearing protective eyewear and demonstrating proper usage and maintenance techniques.

- Ensure Proper Fit: Ill-fitting eyewear can be uncomfortable and may not provide adequate protection. Employers should facilitate fittings to ensure that eyewear is comfortable, snug, and effectively protects the eyes.

- Regular Inspections: Protective eyewear can become scratched or damaged over time. Regular inspections should be conducted to ensure that all eyewear is in optimal condition and replaced when needed.

- Encourage Compliance: Supervisors should foster a culture of safety and compliance, reminding employees to wear their protective eyewear at all times in hazardous environments.

- Create a Reporting System: Employees should be encouraged to report any incidents, near misses, or uncomfortable experiences related to their eyewear or work conditions. This feedback can help improve protocols and safety measures.

Best Practices for Employers – Protective Eyewear for Workers

Best Practices for Employers – Protective Eyewear for Workers

1. Conduct a Job Hazard Analysis

Employers should conduct a thorough analysis of workplace hazards to determine the specific type of eye protection required for each job function. This assessment should include input from employees, as they can provide valuable insight into the risks they face on a daily basis.

2. Provide Training and Education

Employers must educate employees about the importance of wearing protective eyewear and how to select the proper type for their specific tasks. Training should cover the proper care and maintenance of eyewear, as well as guidelines for their use.

3. Ensure Proper Fit

Proper fit is essential for protective eyewear to be effective. Employers should provide various sizes and styles of eyewear to accommodate individual preferences and ensure that employees are wearing equipment that fits correctly.

4. Encourage a Safety Culture

Develop a company culture that prioritizes safety, which can incentivize employees to wear their protective eyewear consistently. Regular safety meetings, reminders, and incentives for safe practices can help reinforce this culture.

5. Regular Inspections and Updates

Employers should regularly inspect protective eyewear for signs of wear, damage, or obsolescence. Providing updates on new technologies or products can also benefit employee safety.

Best Practices for Employees – Protective Eyewear for Workers

Best Practices for Employees – Protective Eyewear for Workers

1. Always Wear Protective Eyewear

Employees must understand the importance of wearing protective eyewear in designated areas and while performing tasks that pose eye hazards. Making it a habit can prevent injuries.

2. Report Damaged or Defective Equipment

Employees should inspect their protective eyewear regularly and report any damage or defects to their supervisor immediately. Using damaged eyewear can compromise safety.

3. Maintain Eyewear Properly

Proper care, including cleaning and storing protective eyewear as per manufacturer recommendations, can prolong the life of the equipment and ensure optimal performance.

4. Understand the Limitations

Employees need to be aware of the limitations of their protective eyewear. For instance, safety glasses may not provide adequate protection against chemical splashes, necessitating the use of goggles.

5. Seek Clarification

If employees have questions about the appropriate type of eyewear or proper use in their specific tasks, they should reach out to their supervisors or safety officers for guidance.

Conclusion

Protective Eyewear for Workers – Eye safety is a critical component of workplace health, especially in hazardous environments. By utilizing the appropriate protective eyewear and fostering a culture of safety awareness, both employers and employees can significantly reduce the risk of eye injuries. Investing in suitable protective eyewear not only adheres to safety regulations but also assures that employees return home with their vision intact, ensuring they can continue to lead fulfilling lives both at work and beyond. Prioritizing eye safety is not just a regulatory obligation; it is a moral imperative that benefits everyone involved.